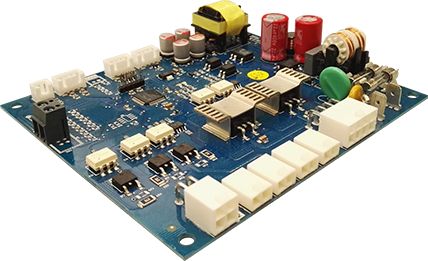

PERSONALIZED ELECTRONIC BOARDS

TAILOR-MADE TECHNOLOGY FOR EVERY REQUEST

We deal with the creation of high quality electronic boards, both of our production and based on our customers' projects. We offer a wide range of services, including sampling, pre-series and customized productions, thanks to cutting-edge equipment such as screen printing with SPI, the melting furnace, the wave welder and the versatile Pick and Place, one of 6500cmp / h for prototyping and small series and one of 18000cmp / h for series production.

We personally follow all the phases of the production process of our electronic boards starting from the design to the assembly, to guarantee you the utmost care and professionalism in the realization.

We carry out tests on our electronic boards respecting current quality standards, carrying out a complete review of the product at the end of each phase, according to the tollgate approval methodology.

Only the product that passes each stage can be subjected to functional testing.

In the last step of the project, our highly qualified staff installs the electronic boards on your system (we never offer third party assembly).

We carry out tests on our electronic boards respecting current quality standards, carrying out a complete review of the product at the end of each phase, according to the tollgate approval methodology.

Only the product that passes each stage can be subjected to functional testing.

In the last step of the project, our highly qualified staff installs the electronic boards on your system (we never offer third party assembly).